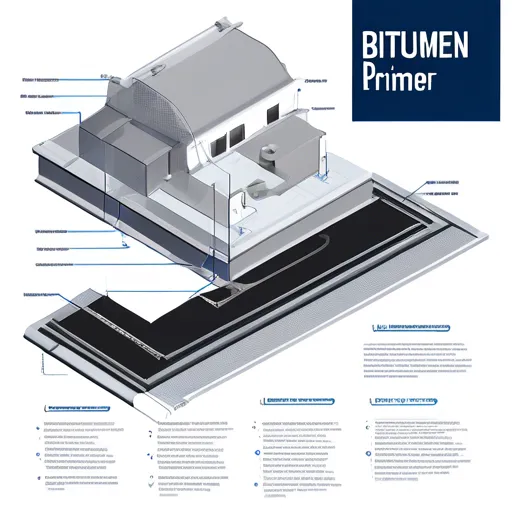

In the realm of industrial coatings and construction, bitumen primer stands as a cornerstone, offering unyielding strength and adhesion that keep the elements at bay. But what exactly is this underrated champion? Herein, we explore the essential functions, diverse types, and savvy application tips of bitumen primer, all while providing a polished guide to enhancing your repair projects.

The Purpose of Bitumen Primer

Bitumen primer serves as a critical preparatory coating, ensuring that surfaces are primed for the application of bituminous waterproofing layers. It’s a blend of bituminous substances diluted to a consistency that allows for easy application on porous materials, such as concrete or metal. In essence, it readies the surface, promising seamless cohesion and longevity.

Main Functions

- Surface Adhesion: By penetrating deeply into the substrate, the primer ensures the waterproofing layer anchors effectively.

- Moisture Resistance: Provides an additional moisture-resistant barrier, fortifying the structure further.

- Dust and Particle Control: Seals dusty or flaky surfaces to ensure better bitumen membrane adherence.

Varieties of Bitumen Primer

While bitumen primer’s basic purpose remains unaltered, the market is replete with different types tailored for specific applications. Knowing these can significantly affect the outcome of your projects.

Types

- Universal Bitumen Primer: Suitable for most applications, it’s a go-to for general repairs and maintenance tasks.

- Solvent-Based Primer: Quick-drying and potent, this type is perfect for environments where rapid turnaround is essential.

- Water-Based Primer: Eco-friendly and low in volatile compounds, ideal for indoor or environmentally sensitive projects.

Practical Application Recommendations

The application of bitumen primer is both art and science. Here, we unravel key tips to maximize the potency and durability of your primer.

Guidelines for Application

- Preparation is Key: Clean and dry surfaces immeasurably improve primer application. Dust and debris can compromise the bond and efficacy.

- Uniform Application: Use roller brushes or spray equipment for an even coat. Uniformity prevents weak points in the waterproofing layer.

- Weather Considerations: Avoid application in wet conditions or extreme temperatures. The primer performs optimally between 10-30°C (50-86°F).

“A stitch, in time saves nine,” aptly sums up the importance of a good bitumen primer. Investing the time and care in this initial step can save substantial labor and materials down the road.

Comparative Insights

Bitumen primer can be likened to the crucial foundation in a skincare regimen—like a toner that primes your face for the application of moisturizers and serums. Just as a car’s performance, such as the Fiat Tipo, relies on meticulous design and preparation, so does the underpinning of a successful construction project hinge upon the prudent choice and use of primer.

Conclusion: Elevate Your Repairs with Expertise

In a world where construction mishaps can lead to costly repairs, the significance of bitumen primer cannot be overstated. Experts and novices alike can boost their project’s resilience by choosing the right type of primer and applying it with precision. Whether you’re tackling a small repair job or embarking on a major retrofit, investing in quality materials and meticulous preparation can dramatically improve outcomes.

If you’re looking to broaden your knowledge on household applications or diverse architectural styles, explore more topics like Arched structures in the interior. And for those venturing into purchasing choices, delve into our Ultimate Guide to Buying Used Peugeot Cars.