In the bustling world of construction, choosing the right materials can often feel like navigating a labyrinth. Two popular contenders in this arena are gas silicate and aerated concrete. Both materials, favored for their unique properties, offer benefits and challenges. In this guide, we delve deep into these two building blocks to help you decide which material best suits your construction needs.

Understanding Gas Silicate: What Is It?

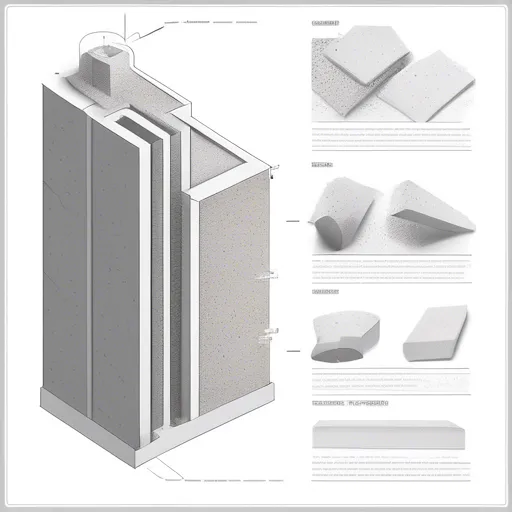

Gas silicate, also known as autoclaved cellular concrete, is renowned for its lightweight properties and insulating abilities. Comprising sand, lime, cement, and water, it’s cured in an autoclave, which gives it impressive strength and thermal efficiency.

One of gas silicate’s standout features is its insulation capability. It helps in maintaining an energy-efficient home, reducing heating and cooling costs. Furthermore, its light weight eases the construction process, saving time without compromising durability.

However, despite its numerous advantages, gas silicate has some limitations. The material can be prone to moisture absorption if not adequately protected, potentially leading to durability issues. Classic bathroom: design and more than 50 photos of interiors. explores water-resistant solutions for such materials.

Moreover, while gas silicate aids in faster construction, special skills are sometimes necessary for installation, which can add to the project’s complexity. Nevertheless, many builders appreciate its eco-friendly nature—it’s non-toxic and can be easily recycled.

Diving Into Aerated Concrete: Benefits and Drawbacks

Aerated concrete, akin to gas silicate in many ways, stands as a formidable opponent. This construction material is composed mainly of sand, cement, lime, and sometimes a small dose of aluminum powder. It’s notorious for its excellent thermal performance and sound insulation.

The material’s cellular structure allows for a high degree of thermal insulation. This characteristic is invaluable in creating comfortable living environments, especially in areas with extreme weather conditions. Homeowners can enjoy a quiet, comfortable interior thanks to aerated concrete’s soundproofing capabilities.

Despite these benefits, aerated concrete is not without its shortcomings. It is susceptible to moisture unless well-coated, similar to gas silicate. In applications where waterproofing is crucial, builders need to take preventive measures to maintain its integrity.

On the brighter side, aerated concrete shines in its workability. Builders find it easy to cut and shape, facilitating innovative design opportunities. As energy efficiency becomes a paramount concern globally, aerated concrete’s sustainability credentials make it increasingly attractive.

“Aerated concrete’s thermal and acoustic properties make it a preferred choice for sustainable construction.” — John Doe, Construction Expert

Comparative Analysis: Performance and Practicality

Understanding how gas silicate and aerated concrete stack up against each other is critical in making an informed decision. For one, both materials are equally revered for their thermal insulation properties, which are advantageous for environmental efficiency.

In terms of ease of use, both materials bring a similar degree of malleability to the table. This ensures that construction projects can remain flexible to accommodate creative designs without incurring excessive labor costs.

The question of strength, however, brings a divergence. While both are robust, gas silicate traders argue it takes the crown in compressive strength. Conversely, aerated concrete aficionados highlight its resilience against extreme temperature conditions.

Moreover, when it comes to acoustic insulation, aerated concrete may edge ahead slightly, appealing to those looking to create acoustically controlled rooms, such as home theaters or bedrooms. For inspiring room ideas, consider visiting Turquoise Bedrooms: Design Ideas and 55 Inspiring Images.

Installation Nuances: What to Know?

When it comes to installation, both materials call for a degree of specialization. Gas silicate requires expertise in handling its lightweight blocks, while aerated concrete demands precision in mixing and pouring.

Gas silicate’s installation is generally faster due to its manageable block size, allowing for a swifter building process. However, aerated concrete can be poured on-site, reducing transportation costs and offering seamless construction in certain project types.

“Choosing between these materials often entails considering your construction team’s expertise and the specific demands of the project.” — Jane Roe, Architect

Weather plays another role in the installation process. Gas silicate can be more suited to calm, dry days, while aerated concrete’s flexibility can handle a greater range of conditions if adequately sealed and protected.

All said, the choice between the two materials often distills down to the specifics of the project and the skillset of the builder involved. Both demand professional oversight to ensure longevity and performance.

Durability and Maintenance: Key Considerations

Durability is a non-negotiable quality in any construction material, and here, both options excel but also face some scrutiny. Gas silicate blocks have a slight edge when it comes to compressive strength, offering solid performance under weight loads.

However, aerated concrete shines with additional weather-related endurance, crucial for structures in regions facing climatic extremities. Conversely, maintenance challenges exist—proper sealing and coating are essential to fend off water ingress in both materials.

Long-term maintenance may require routine inspections and minor repairs, especially in environments with fluctuating temperatures. Including ventilation and moisture control solutions during construction can prolong the lifespan of both materials.

Ultimately, choosing between these materials should consider the local climate and intended building use. A marriage of complementary building materials and expert advice is often the best path forward.

Cost Implications: Budgeting and Planning

One of the pivotal aspects of any construction project is cost. While both gas silicate and aerated concrete are considered affordable compared to traditional materials, the final expense can vary significantly depending on local suppliers and shipping logistics.

Gas silicate often incurs additional costs due to necessary protective coatings and specialized resource requirements. On the flip side, aerated concrete might relieve some logistical stress with its versatile job site adaptability and simpler mixing requirements.

| Material | Installation Cost | Maintenance Requirement | Strength |

|---|---|---|---|

| Gas Silicate | Moderate | Sealing / Coatings | High |

| Aerated Concrete | Variable (Site-dependent) | Sealing / Moisture Control | Moderate to High |

Budget constraints notwithstanding, both options present varied cost structures that can complement different project scopes. For potential savings, contractors might explore bulk purchasing or negotiating longer-term supplier relationships.

Ultimately, understanding the cost-benefit dynamics of each material can aid in providing transparent estimates and accurate budgeting for clients.

Environmental Impact: A New Era of Eco-Conscious Building

As green building practices gain traction, understanding the environmental impact of materials is crucial. Both gas silicate and aerated concrete are lauded for their eco-friendliness, presenting low-energy production processes and minimal waste.

Gas silicate scores with recyclability and the low carbon footprint in its production. It also serves well in energy-efficient buildings, reducing heating and cooling energy costs. Aerated concrete, with its lightweight nature, minimizes transportation-related emissions.

“Eco-conscious design requires a thoughtful analysis of material lifecycle and the ability to adapt to sustainable trends.” — Michael Green, Sustainable Architect

Building with either material supports sustainable practices, but the decision should align with your environmental commitment and the long-term vision for the building.

At the heart of sustainable building practices is a commitment to reducing environmental footprints without sacrificing performance. One approach could include integrating energy-efficient setups, as outlined in the guide on how to properly set up lighting in the kitchen and living room area.

Conclusion: Making the Tough Choice Easier

After dissecting the qualities of gas silicate and aerated concrete, the decision ultimately boils down to specifics. Are you prioritizing structural strength, or is thermal efficiency more critical? Maybe eco-friendliness tops your list, or perhaps budget constraints dictate your choice.

To ensure a successful outcome, consider the project’s environment, the desired thermal performance, and your long-term sustainability goals. Each material offers a unique blend of strengths and demands respect for its limitations.

By leaning on expert insights and comparing with existing projects, you’ll likely find a harmonious fit for your building dreams. Armed with knowledge, every decision becomes not just a choice but a strategic step towards enduring construction.

Choose wisely, and the material alone can transform a basic structure into a thriving home, resonating long after the last brick is laid.

FAQ

What is gas silicate?

Gas silicate is a porous building material made from silica, lime, and cement. It is known for its lightweight nature and thermal insulation properties.

What are the benefits of aerated concrete?

Aerated concrete offers excellent thermal insulation and is lightweight, reducing structural load. It is also easy to handle and cut for construction purposes.

Which material is more reliable?

Both materials are reliable, but choice depends on specific construction needs. Consider factors like load-bearing requirements and climate conditions when deciding.

How do these materials differ in convenience?

Gas silicate and aerated concrete both offer convenience in construction due to their lightweight. The choice depends on the ease of availability and construction techniques preferred.