What should be taken into account when finishing?

A typical ceiling of a house made of logs or timber is a lightweight structure of beams and plank flooring, under which insulation is laid (mineral wool, foam, expanded clay). Some houses have a self-sufficient ceiling that can do without finishing, while others are poorly protected by a roofing cake, so they require serious insulation and finishing work inside. This is the first thing to consider.

The second important circumstance is the mobility of wood. It inevitably shrinks and shifts. To avoid cracked walls and ceilings that have moved apart, they do not start decorating them right away. A house built in the summer is finished in a year, and winter buildings – in 7-8 months.

The third aspect is the purpose of the premises. The same material is not suitable for covering the ceiling in the entire house. In addition to living rooms, there are living rooms with stoves and fireplaces, kitchens, verandas, storage rooms, bathrooms, baths and saunas. All these places have their own microclimate.

And finally, the finishing of a log house should, if possible, not take away its advantages and compensate for its disadvantages. The first include environmental friendliness, a pleasant smell, natural humidity control, good sound insulation. The second ones are fire hazard, susceptibility to rotting, drying out, warping and insect attacks.

The photo shows a living room in a cottage made of light timber with a complex original ceiling finished with Euro lining

What materials are suitable?

If the thickness of the log or timber used in the construction of the house, as well as the quality of external insulation and waterproofing allows you to reduce the interior finishing work to a minimum, most owners prefer to do so. And wood goes best with wood. Therefore, you can finish the ceiling with clapboard, unedged board, solid wood, planken or plywood.

In houses that have undergone large-scale interior finishing works that have hidden all the beauty of wooden walls, it is easier to adhere to a similar approach to decorating ceilings. You can cover them with plasterboard, finish them with plastic panels, decorate them with stretch fabrics.

Clapboard

It is wooden slats with a longitudinal groove on one end and a tongue of the corresponding size on the other. The elements are inserted into each other during installation and are usually attached to the timber lathing.

There are four classes of lining:

- Extra;

- A;

- B;

- C.

The higher the class, the more expensive the wood used (oak, beech, hornbeam, maple, walnut) and the fewer defects are allowed.

When choosing budget lining made of coniferous wood, it is better to buy it with a small reserve in case you come across knotty, curved slats.

Even in an already settled log house, you cannot sheathe the ceilings with lining end-to-end with the walls and load-bearing beams, since the slats themselves will still “walk”, taking root in a new place. Gaps can be easily masked with wooden baseboards.

In the photo, the craftsman is installing lining on the insulated ceiling of a log house by attaching it to a wooden lathing

Drywall

There is no need to explain what drywall looks like, and its composition is obvious from the name. These boards are so popular because they allow you to quickly neutralize unevenness, hide communications and prepare the base for finishing.

Drywall is breathable, dampens noise and vibration well, maintains a comfortable level of humidity in the house, takes complex shapes when wet with water, allows you to create interesting designs and is inexpensive.

Drywall boards are usually mounted to a metal lathing. They do not take much time and effort to install, but they mercilessly steal centimeters of height, especially in rooms with very uneven surfaces.

A plasterboard-covered ceiling in a wooden cottage can become the highlight of the interior, thanks to decorative plaster, plaster moldings, a fancy shape, several levels, halogen lamps, tension elements or original 3D-effect panels.

The photo shows a plasterboard ceiling with an octagonal niche and halogen lamps, installed in the lobby of a wooden cottage

Stretch ceilings

Polyvinyl chloride or polyester serves as a base. The first one can withstand temperatures from +5 to +50°C, the second one – from -50 to +40°C, but it is also much more expensive and lasts longer (up to 25 years versus 10 for PVC).

Stretch ceilings can have any color or pattern, but different surfaces:

- glossy;

- matte;

- satin.

Light glossy film helps to visually raise the ceiling, fill the room with light. Matte and satin canvases look noble and elegant.

Advantages of stretch ceilings:

- expand the choice of styles when decorating rooms;

- installed with a heat gun in a few hours without construction waste;

- protect from flooding in case of roof leakage;

- mask utility lines;

- do not attract dust and dirt, easy to maintain;

- improve sound insulation.

Disadvantages:

- require high-quality waterproofing of the roof and regular heating, that is, you need to live in the house constantly, otherwise mold and condensation will appear;

- can be damaged by sharp chips falling from the ceilings, and then the canvas will have to be changed completely;

- not installed near heating pipes, stoves and fireplaces (except for heat-resistant canvases);

- relatively expensive.

The photo shows a bedroom in a private log house with a fabric stretch ceiling strewn with white flowers

Unedged board

Logs are sawn lengthwise into 20-30 mm thick sheets, the bark is removed along the edges or left intact, the blanks are dried, planed, sanded and cut into fragments up to 4 m long. Both valuable and affordable wood species (pine, aspen) are used for manufacturing.

Unedged boards with removed bark are usually used for cladding ceilings. The slats have an interesting pattern with an uneven edge, and these advantages can be easily emphasized with varnishes, paints and stains.

Unedged boards can be used to decorate a house in an antique style, enhancing the impression of simplicity of the interior. This solution will be successful for rustic styles, such as country, chalet or Provence.

The board is mounted directly on the rough ceiling or on a wooden lathing using galvanized nails or self-tapping screws. The lamellas are laid in two layers with an offset so that gaps are not visible.

It is not necessary to cover the entire ceiling with unedged boards. You can highlight a separate fragment and zone the room in this way.

The photo shows an attic bedroom for two, beautifully finished with unedged boards and ceiling beams made of logs

MDF panels

They are made from wood chips with the addition of urea resins by pressing under high temperature and pressure. The density of MDF is impressive – 600-800 kg/sq. m. Ceiling panels come in slatted, square and rectangular shapes.

By type of covering, they are divided into:

- veneered panels – covered with natural veneer made of valuable wood species, expensive and impressive, suitable for a living room or bedroom;

- laminated – protected with a polymer film, waterproof, imitating the structure of wood or natural stone, suitable for kitchens and bathrooms;

- painted – affordable, with a wide range of colors, but unstable to high humidity and temperature;

- “paper” – covered with paper or cardboard, budget and attractive, but suitable only for dry, warm rooms.

Choosing the finishing of ceilings in a wooden house with MDF panels, you will make a smart decision, because they are varied in design. and cost, safe for health, save from noise, resistant to parasites and mold, durable (10-20 years), easy to install and maintain. But still, it is wood – the problem of fire hazard remains.

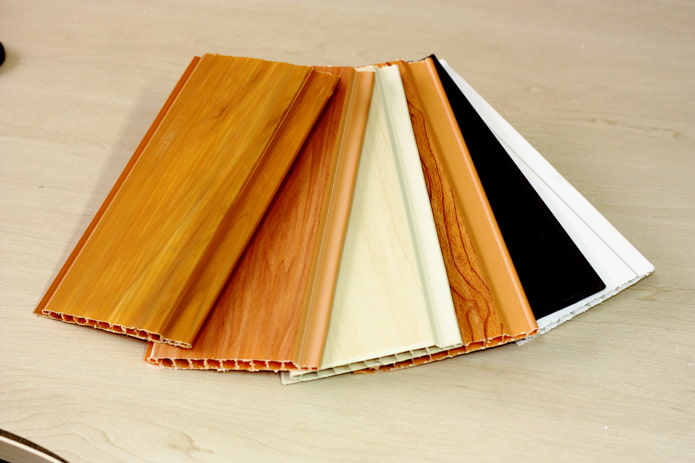

PVC panels

These panels are formed by two thin sheets of polyvinyl chloride, between which there are several perpendicular stiffeners, that is, the product is partially hollow and therefore very light. On one side along the part there is a large fastening strip for mounting to the steel lathing, and on the other side there is a small one for adhering the elements to each other. The connection can be seamed or seamless. In terms of shape, PVC ceiling panels are slatted, sheet, and tiled.

In terms of appearance, they are divided into:

- monochrome – the pigment is included in the composition of polyvinyl chloride, so the coating does not fade or turn yellow over time;

- painted, patterned, and varnished – they look more impressive, but quickly lose their gloss and become covered in scratches;

- laminated – covered with a thin film that imitates the structure of wood or stone, they also fade or deteriorate quite quickly from mechanical damage.

The advantages of covering ceilings with plastic panels are minimal effort and money, relative durability (up to 10 years), resistance to moisture, the ability to easily replace a damaged element or paint over a defect.

But there is a risk of encountering low-quality panels that are easily flammable and also emit into the air dangerous compounds.

Planken

This word translated from German means “boards”, and the finishing material fully justifies its connection to Germany as a stronghold of quality. Planken is carefully planed, sanded and dried boards with slightly rounded edges (3-5 mm).

There is no tongue and groove connection, which improves ventilation of the ceiling. The ends are straight or oblique. In the latter case, moisture from the roof will be well drained outside.

Planken is usually made of larch or pine, lasts up to 50 years, looks expensive and respectable, comes in any color, even black and white, is not afraid of heat, frost, pests or humidity.

Planken is produced in four grades:

- Extra;

- Prima;

- AB;

- Economy.

Even the last option cannot be called low-grade, it is of decent quality. You’ve already guessed about the disadvantages of planken – in addition to flammability, it’s quite expensive.

Plywood

Several thin layers of wood are glued together so that the fibers are mutually perpendicular. This is necessary to increase strength and resistance to deformation under the influence of temperature and humidity changes.

Plywood comes in different classes and sizes, imitates the texture of natural wood, and is quickly mounted by hand, including using the frameless adhesive method. If the appearance leaves much to be desired, you can cover the ceiling in a wooden house with thin plywood, and then paint it, paste over it with decorative tiles or wallpaper, or plaster it.

The main advantage of plywood is its friendly price, but a very cheap grade will not be moisture-resistant, impregnated with fire retardants, or environmentally friendly.

Casein plywood can be called safe for health, and the most affordable, bakelite, can become a source of harmful fumes.

How to decorate the ceiling?

Sometimes, to get a beautiful ceiling, it is better to just leave it alone, especially if powerful logs and rough boards are the best decor for the chosen style of a wooden house.

Elements of the ceiling structure can be emphasized by painting, for example, dark beams on a light background. This allows you to make the room more airy. If you had to cover the ceiling from the inside to insulate it, you can add false beams for finishing.

The greatest scope for imagination is provided by multi-level ceilings of complex shapes, where different coverings can be combined, for example, clapboard and stretch fabrics with a stunning pattern. Correctly placed spotlights will help to frame the composition. This is especially important in the case of walls and ceilings covered with wood, as it softly diffuses the light.

Beautiful examples for inspiration

Decorative structures made of stuffed beams look impressive: lattices, geometric figures, but they make low ceilings even lower. You can decorate the ceiling in a wooden house with alfresco finishing: panels, carving, end grain, rolling an ornament through a stencil.

Massive forged chandeliers that send light upwards, or hanging lampshades made of natural materials look especially advantageous in such interiors: wicker, imitating coarse burlap.

The ceiling decoration in a wooden house can become one of the most expressive elements of the interior, although at first glance it seems that the owners of such a home have a choice not big. And yet we vote for the natural charm of wood – let the finishing steal as little of this beauty as possible.

Now reading:

- Comprehensive Guide to Buying Lancia Used Cars

- Stylish kitchen with a bar counter: design ideas and 60 photos of interiors

- Kitchen Buffet: 30 Design Ideas and Photos for Inspiration

- Linoleum for the kitchen: 50 inspiring photos and design ideas in bright and dark shades.

- Combining colors for kitchen interior: recommendations, tables and diagrams