General information

High-quality insulation of the floor in a private house at one fell swoop covers two primary needs of those who live in it: it increases comfort and reduces heating costs. Low-quality… the history of house building knows of real cases when a cottage was ceremoniously put into operation, and in the very first heating season the numbers in the bills skyrocketed, and comfort increased not in the house, but around it: snow melted on the blind area in the middle of winter and green grass broke through.

The quality of insulation is tied primarily to efficiency, safety – in all senses, from fire safety to medical safety – and the durability of the materials used. In addition to this, the most advanced consumers, inclined to follow global trends, pay attention to such parameters as environmental friendliness – it is important for them that the environment does not suffer during the manufacturing and operation of construction products.

If there is demand, there will be supply – this is how thermal insulation appeared on the market that combines all the listed properties: foamed polyisocyanurate (PIR). In Russia, it will be easiest and most convenient for a private consumer to find and buy products from the domestic company TECHNONICOL – LOGICPIR thermal slabs.

What is important to know about LOGICPIR?

LOGICPIR is a new generation of thermal insulation, an improved version of polyurethane foam with improved fire-fighting characteristics. This material has very low thermal conductivity – only 0.022 W/m*K, – therefore, with the same layer thickness, it provides a higher level of thermal protection than traditional insulation materials.

LOGICPIR has a composite composition: a durable rigid layer of hardened polymer foam is provided with a double-sided soft facing, which gives the slabs additional useful functions. As a rule, such thermal insulation is supplied with profiled ends during production to prevent the formation of cold bridges at the joints of the slabs and to ensure ease of installation.

LOGICPIR thermal slabs with vapor-impermeable alumina laminate lining (foil plus polyethylene) are recommended for installing floors. In essence, the result is a “three-in-one” material: thermal insulation, vapor barrier, and infrared reflector.

What are the advantages of LOGICPIR for floor insulation?

It goes without saying that LOGICPIR thermal slabs generally meet the strictest standards applicable to the internal insulation of residential premises. Safety is paramount here: it is a fire-resistant and biostable material with a neutral and stable composition. LOGICPIR does not emit harmful substances into the atmosphere even when heated to 110 degrees – confirmed by laboratory tests.

However, it is possible to list specific advantages of such boards, typical precisely for floor insulation.

- Thanks to the low thermal conductivity of LOGICPIR, the required level of thermal protection can be achieved by using boards of minimal thickness (literally 3-5 cm). The advantages of this circumstance begin already in the hardware store: you will not have to overpay for the extra volume of material. And the entire structural pie of the floor with such a “filling” will be thinner – therefore, it will be possible to preserve the ceiling height in the room as much as possible.

- The material is impermeable to steam – this is what the unique closed-cell structure of the hardened polymer foam PIR makes it, and the laminated foil of the facings enhances the effect. Therefore, a floor with LOGICPIR does not require a special vapor barrier layer – it is enough to carefully glue the joints of the slabs with aluminum tape to obtain a completely sealed structure.

- The reflective ability of the foil surface of the slabs allows them to work as an “infrared mirror” and gives a bonus to heat retention.

- LOGICPIR slabs are rigid and durable. Firstly, such thermal insulation is easy to install – you can easily move along its surface. Secondly, the structure as a whole will be especially reliable and durable – there is no risk that the floor will sag under some particularly massive cabinet during operation. After all, PIR, with its compressive strength of 150 kPa, which corresponds to a load of 15 tons per square meter, is easily capable of withstanding the weight of three average elephants.

- In the design of a “floating floor”, LOGICPIR thermal slabs, in addition to insulation, perform the function of protecting against impact noise (relevant for rooms located below the insulated ceiling), preventing direct contact between the screed and the ceiling.

Insulation of the insulated floor

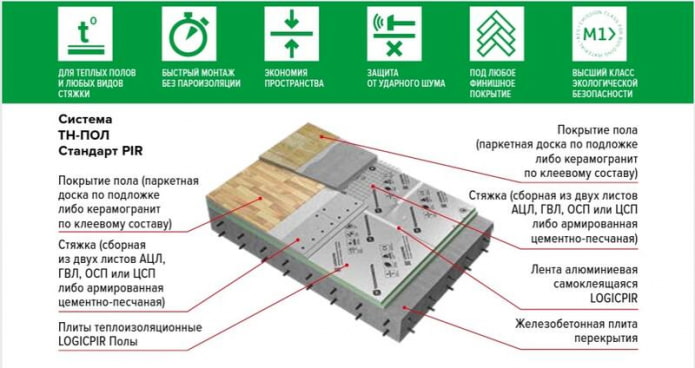

Let’s consider the example of the TN-Pol Standard PIR system from TECHNONICOL.

The first stage of installing an insulated floor using the TN-Pol Standard PIR system is preparing the reinforced concrete base. The surface is cleaned of debris, cracks are sealed.

Next, it is necessary to pay attention to the places where the floor is connected to other structures (these can be partitions, walls, through pipes, etc.).

To obtain an effective “floating” floor design and minimize the spread of impact noise, foamed polyethylene spacers with a thickness of 8-10 mm are installed. Their height should reach the planned level of the final floor covering.

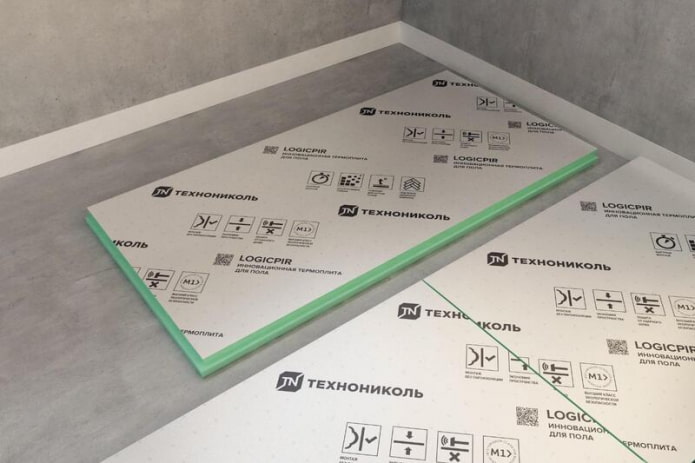

LOGICPIR thermal slabs are laid on a cleaned concrete base, aligning the L-edges so that there are no through gaps. Installation must be carried out with a staggered seam: each row is shifted relative to the previous one – there should be no cross-shaped joints.

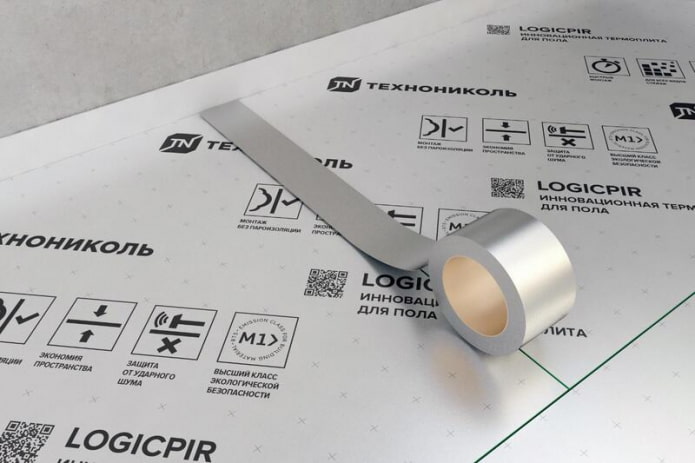

The joints of the slabs are hermetically sealed with aluminum tape. This will help prevent condensation in the thickness of the structure and, thus, protect it from moisture and the dangers associated with it – destruction of materials, formation of mold and mildew colonies.

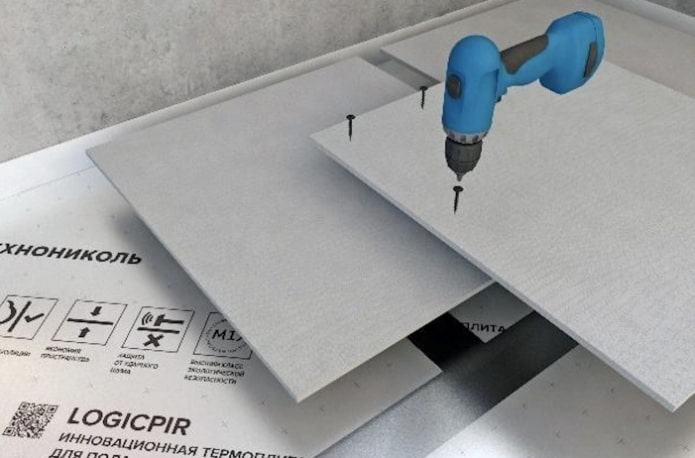

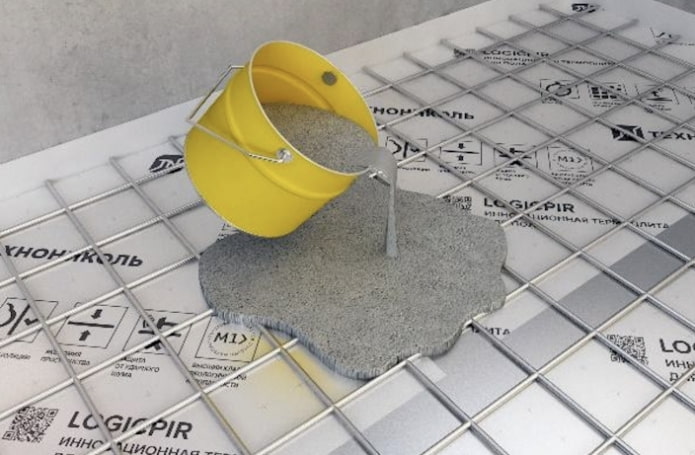

The next step is the installation of a screed, the purpose of which is to evenly distribute the load on the floor. It can be either cement-sand with reinforcement with a metal mesh, or prefabricated dry. In the second case, sheet materials are used: plywood, OSB, ACL, CSP, GKL, GVL – they are laid in two layers, avoiding the coincidence of joints, and these layers are fastened together with self-tapping screws.

Laminate, parquet board, ceramic tile, linoleum, etc. are used as the finishing coating – all these materials are installed in accordance with the manufacturer’s instructions, using the appropriate substrates and fastening methods.

The TN-Pol Standard PIR system can and should be used not only in cottage housing construction. Such insulated floors on a reinforced concrete base are also suitable for city apartments – they will be especially useful on the ground floors, where they will allow residents to forget about all the disadvantages of living next to a cold basement. In addition, this construction solution can easily be extended to office spaces, retail areas, entertainment venues and catering establishments, social institutions, etc.

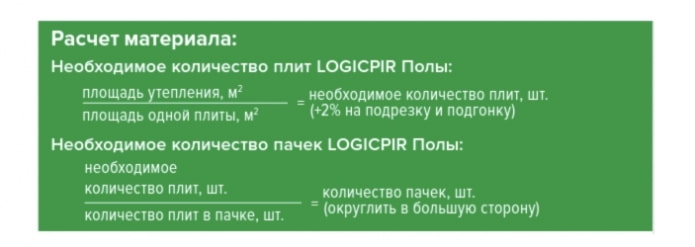

See below for the calculation of material per square meter.

Now reading:

- 75 images of chandeliers for decorating living rooms, bedrooms, kitchens and other rooms.

- Design of 18 sq. m. studio apartment: zoning and 50+ photos of layouts

- practical ideas for efficient storage of cosmetics and Ordnung in your collection.

- What cookware to choose for induction cooktops? – 6 key tips before buying.

- Best Small Closet Layout Ideas and Organization Tips