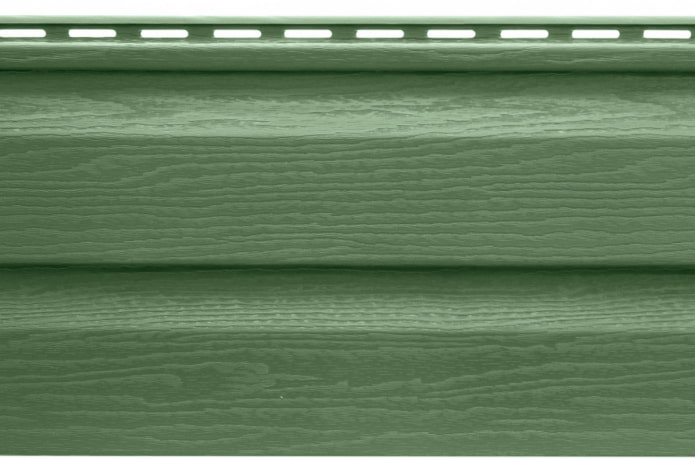

Vinyl siding

Let’s start the review with one of the most inexpensive and popular options – vinyl siding. Such facade panels are made of polyvinyl chloride – the same material from which plastic panels for interior decoration are made. The characteristics of siding and PVC panels are also similar:

Ceramic siding

Ceramic tiles and porcelain tiles are the most wear-resistant, reliable materials for finishing the house from the inside. Unfortunately, it was impossible to use them outside the house – and not because of the material itself, but because of the composition of the glue, which simply could not withstand temperature changes, precipitation and other various environmental tests. But Japanese scientists set out to find a way to use ceramics in facade finishing… and solved this problem!

Ceramic siding is the name given to special panels that consist of a mixture of several types of clay with natural improving components. Ceramic siding is attached to a special lathing – this type of installation is called a ventilated facade and allows you to avoid many troubles.

Acrylic siding

In appearance and many characteristics, acrylic siding (ASA) is similar to vinyl, but with one huge advantage – acrylic is not exposed to the negative effects of direct ultraviolet radiation. Simply put — it doesn’t fade in the sun!

Metal siding

Metal siding is one of the oldest and most popular types used in finishing residential and industrial buildings. Since metal was initially used mainly for the improvement of warehouses and factories, it can rarely be found on private homes. And in vain — this type of siding has a lot of advantages!

Depending on the raw materials used, metal siding is divided into galvanized steel panels, ~0.5 mm thick, and aluminum siding. Both materials are treated with a polymer coating: the polymer layer protects the metal from environmental influences, serves decorative purposes, painted elements are less common.

Wooden

100% environmentally friendly option, used for cladding houses since time immemorial. Wooden panels are available in various forms, from which everyone can choose the one that suits their style and cost:

- False timber. Flat durable boards with tongue and groove fastening. Imitation of profiled timber. The width for facades is selected from 140-150 mm.

- Block house. The boards, flat on the inside and rounded on the outside, have tongue and groove fastenings. They imitate rounded beams.

- American. The appearance of this wooden lining in section resembles herringbone laying: the lower side of the panels is narrowed (example in the photo), due to which such an unusual effect is achieved.

- Shipboard. A familiar form for siding, imitating the finish of a ship’s deck. Rarely found in wood.

Important! Due to the ease of processing, wooden elements are fastened vertically, horizontally and even diagonally.

The main advantage of facing wood is that it does not require additional insulation, unlike other types of siding. Wood serves both as a decorative finish and as a thermal insulation material.

Fiber cement siding

It’s easy to guess what fiber cement consists of from the name – a cement mixture with the addition of cellulose fibers (paper) and mineral substances (improvers).

Such symbiosis works for quality: cellulose gives the material elasticity, ordinary cement – strength. In essence, fiber cement siding is similar to ceramic siding, but has its own unique set of features:

Insulated

We’ve talked a lot about the importance of insulation when covering buildings with siding, but we’ve missed the main thing – panels are already insulated! Which significantly enhances the properties of the cladding.

Unlike conventional options, this one has a special polyurethane foam applied to the inside – it’s dense enough to retain heat and block noise from the street. Insulated siding alone may be enough in the southern regions, but in central and northern latitudes the house will still have to be additionally insulated: however, you can save on materials by choosing less dense and frost-resistant ones. After all, the insulation of the panels themselves takes on 30-40% of the work on general thermal insulation.

The installation of insulated models is no different from the usual ones – installation is carried out on the frame. The sizes of individual parts, additional elements are also standard for a specific company / country of manufacture.

Base

Base siding is also called facade panels: they usually imitate brick or stonework. Initially, basement panels were more expensive than regular ones, so they were used exclusively for cladding the bottom of the building – after all, this is where strength, ease of maintenance and a beautiful appearance are most needed. It is due to the popularity of this solution that the panels were called “basement”.

But with the development of technology, basement siding has become little different from facade siding (the latter began to be made more durable, production prices decreased) – so today it can be used on the entire house without much harm to the budget.

Siding is a simple and beautiful option for decorating a house from the outside. With its help, you can decorate the exterior in just one season, and thanks to a special technology, installation is not tied to the time of year – so you can work at any time!

Now reading:

- Children’s room design: ideas for repair, zoning and design

- Eight of the most elegant interiors created by famous personalities

- creative ways to decorate the septic tank hatch on your property.

- Brown shades in the interior: combination options and photo examples

- Discover the All-New BMW X1: A Luxury Compact SUV