What can be used to cover a stove?

The facade parts of stoves that provide heat using coals and wood logs are elements that always have a huge number of different requirements.

Non-flammability, strength, durability, aesthetics, protection from physical and chemical changes under the influence of temperature, hygiene, ease of everyday use – there are many criteria for choosing the appropriate materials. They must withstand intensive care using caustic cleaning agents, cope with an impressive number of thermal cycles of heating and cooling, and also increase the level of fire safety of the premises.

Surprisingly, there are enough facing materials that have all of the listed qualities. They are sold in specialized stores in the form of ready-made pressure blocks, overhead panels and dry solutions. The most popular options for facing a home stove or fireplace include:

-

mixtures for plastering the surface;

-

ceramic tiles with even corners;

-

facade bricks;

-

natural or artificial stones;

-

functional clinkers;

-

steel sheets;

-

majolica;

-

simple types of whitewash;

-

tiled slabs;

-

terracotta tiles for walls, etc.

All the options presented have their own advantages and disadvantages. You need to choose very carefully, based on your current budget, the quality of the desired result and the type of heating used.

Plaster

The cheapest, but less attractive and not very durable solution is to simply plaster the stove for subsequent application of paint and varnish. It allows you to get a more or less decent coating, which, however, will become unusable over time. You can cope with the work on cladding the facades yourself, without involving experienced craftsmen. The facing material has many obvious advantages:

-

wide availability – the mixture is presented in the assortment of any specialized shopping center;

-

affordable cost – savings on the purchase of expensive tiles and heat-resistant panels;

-

significant versatility of the frame elements – the ability to ennoble the stove structure of any popular type;

-

increased functionality – the solution increases the thickness of the tiles and the surface of the brick walls of the device, improving its efficiency.

Plaster provides the proper degree of fire safety, including through sealing, with a subsequent reduction in the chances of carbon monoxide penetration into the room.

Tiles

Another popular option, regularly found in private homes of various sizes. Tiles are considered one of the most versatile materials for stove cladding. They have a whole list of various advantages: from high heat resistance and mechanical stability to the ability to accumulate heat and low water absorption. Ceramic blocks of this format are divided into five large groups:

-

tiles – a budget facade, when purchasing which you should focus on the key parameter of heat resistance;

-

granite tiles – tiles filled with all kinds of additives in the form of crushed fine-grained stone chips;

-

chamotte – heat-resistant porous bases with a brittle structure, laid in places with maximum temperature exposure;

-

terracotta – a simple glazed composition, distinguished by a characteristic reddish-brown hue;

-

clinker – a clay analogue, made by pressing with subsequent engineering thermal firing.

Aesthetic image, affordable price, low weight, the ability to accumulate and give off heat, the highest durability — the universal material has enough obvious advantages.

Let’s take a closer look at the most popular of them — tiles. It is in the highest demand, but does not have any impressive characteristics. Tiles are a strong middle class of materials intended for facing stove structures. It does not have the proper heat resistance and mechanical stability, and the most heat-resistant options are highly dependent on banal temperature changes.

During use, the panels can crack and lose their original, rather refined and neat appearance. In addition, experts do not recommend purchasing products larger than 20×20 cm. Such models are absolutely not intended for use in cold rooms.

That is why it will not be possible to equip a stove in a guest house or in a summer kitchen using this building material. The only significant advantage of these blocks is the ease of installation. Even a beginner, initially far from the events on decoration of the corresponding structures, will be able to cope with the installation of tiles.

Facing brick

One of the most ancient elements used in various areas of construction. It is practical, attractive and durable. Allows you to create beautiful facades for heating and cooking stoves running on solid fuel. It is characterized by a whole list of advantages:

-

incredible durability – a base laid by a real experienced craftsman will serve its owner for up to 100 years;

-

outstanding heat resistance – resistance to any fire sources, reliable protection from changes under thermal influence;

-

one hundred percent environmentally friendly – complete safety, production from natural components (clay, lime, quartz sand);

-

resistance to temperature fluctuations – protection from structural damage to corners that appear as a result of heating and cooling cycles;

-

the widest assortment – the ability to purchase decor that fits into any modern interior.

The only drawback of the material is the highest requirements for installation. The maximum permissible deviations in width and length in a brick oven vary around 3 and 4 millimeters, respectively.

Clinker panels

A general name for building compounds manufactured using a special Dutch technology. Finishing blocks are made from shale clays using high-temperature firing. According to technical characteristics, they are close to natural stone. The main operational advantages include:

-

fire resistance — no loss in operational properties when exposed to significant temperatures;

-

resistance to mechanical damage — reliable protection against scratches, fractures, chips, aggressive chemical environments and adverse weather conditions;

-

thermal expansion coefficient — standard values, fluctuating around 6-9% (the value depends on the number of additives);

-

highest heat capacity — the ability to accumulate thermal energy, with subsequent release into the external space;

-

protection from ultraviolet radiation — resistance to solar radiation and fading.

If all manufacturing technologies are observed, the cost of such material will be an order of magnitude higher than that of ordinary ceramic tiles. In addition, its installation is carried out using special finishing mixtures and solutions.

Design from natural or artificial stone

Fireclay panels, tiles, marble and other types of stone are a list of compositions used to solve problems of arranging the walls of stoves at all times. Moreover, specialists paid special attention to the last component.

The fact is that natural or artificial stone is included in a kind of premium segment. Its inclusion in the list of the best solutions for decorative finishing of solid fuel furnaces is due to the presence of an impressive list of advantages:

-

environmentally friendly and 100% chemical and sanitary safety;

-

optimal weight proportions, easy installation, complete drying speed;

-

incredible resistance to mechanical damage;

-

no side effects when heating and cooling;

-

easy maintenance, does not require particularly caustic cleaning agents and reagents;

-

durability, faithful service to the owner for many decades;

-

large selection of textures, easy interaction with any interiors;

-

low percentage of water absorption, increased efficiency of thermal installations.

The only drawback of natural or artificial stone is, of course, the cost. You can only consider such a solution if you have a reasonable budget. Otherwise, you should pay attention to less expensive analogues – tiles, clinker or fireclay.

Metal frames and sheets

Metal is a thing that can be used both for cladding and for laying stoves. Preference is given to galvanized sheets or their aluminum analogues. The key operational advantages of the material include:

-

low cost;

-

speed with which the surface can be laid;

-

ease of installation;

-

aesthetics (after painting);

-

the possibility of using ribbed sheets;

-

hygienic and easy to maintain.

However, this material has never been classified as a premium group. Experts try to avoid it, relying on an impressive list of main disadvantages:

-

excessive heating of furnace wall dampers, firebox doors and ash pits;

-

short-lived paints and varnishes that need updating;

-

poor interaction of ordinary paint and aluminum;

-

additional corrosion of panels laid inside.

In houses with furnaces assembled from metal sheets, an increased heating rate is observed. However, the efficiency of the structure is leveled by rapid cooling and increased fuel consumption.

Whitewashing

The simplest, fastest and cheapest tool for facing the brick surface of the stove is, of course, banal whitewashing. This solution does not have any special advantages, since it rather belongs to the class of budget analogs. The only significant advantage of the dry whitewash mixture is the ability to lay it yourself. All activities are carried out step by step in the simplest instructions, which even a beginner can handle. As a result, the owner of the house gets:

-

a fairly aesthetic cooking chamber (it acquires a beautiful appearance after painting);

-

not very durable, but quite a strong structure that can serve the owner for at least several years;

-

a good set of fire safety standards – the solution seals the cracks, preventing the penetration of carbon monoxide;

-

increased functionality – the component makes the walls thicker, expanding the time regulation of heating and cooling.

In general, we are talking about an inexpensive, but at the same time popular option with its own advantages. Many people use it as a temporary solution, given the current budget shortage.

Facade terracotta

A material made from simple white clay and fired at high temperatures (from 1,000 °C). A fairly difficult and lengthy technological process gives the desired result – companies produce smooth, dried, decorated and polished slabs that can withstand impressive thermal and mechanical loads.

In addition to an interesting structure, the block is characterized by an unusual appearance. Its shade resembles a simultaneous mixture of the color of classic brickwork, wild stone and natural wood. The main operational advantages of this solution include:

-

one hundred percent ecological purity and safety – can be used in places where there are children or people with identified allergies;

-

elementary care and maintenance – a fairly dirty base color, applied in a thin layer, indicates that the owner of the stove will not have to spend personal time on thorough cleaning;

-

rich and aesthetic appearance – the material fits into any modern interior, ennobling a heating device operating on solid fuel;

-

the widest range of textures – manufacturers offer huge catalogs of products, offering consumers, including analogs that imitate natural wood or stone;

-

increased efficiency – the substance doubles the heat transfer parameters of the heating module, allowing the room to warm up much faster.

Terracotta has practically no disadvantages, especially if you do not pay attention to its porosity. If handled incorrectly, the edges, side installations of the tiles and the walls of the stove simply crumble.

Recommendations for stove design

A person choosing a stove for his own home must take into account a whole list of various indicators.

- First, you need to understand the features of the design itself. Cooking chambers can be corner, wall-mounted, front, rotary and built-in.

- Second, you should understand what features the selected unit has. It may feature unique flue directions, double walls, cold handles, cooking rings, air flow controls and large viewing windows.

In order for the module to fit into the current interior, the owner of the cottage will have to pay close attention to the lists of standard design projects:

-

French Provence style – we look towards exclusively natural materials, choose monochromatic light and pastel colors.

-

The aesthetics of rustic natural stones — we install a stove in the living room, creating a space for evening get-togethers. We refine everything with natural wood, and equip a terracotta or clinker cooking chamber.

-

Italian country — we combine sunny, simple and modest shades with a fairly rich design. We finish the surfaces with Venetian plaster, trying to add as much stone as possible.

There are really many options for refining the stove. But a high-quality design project can be made independently only on the recommendations of experienced craftsmen.

How to tile a stove?

The process Do-it-yourself stove cladding does not seem difficult, especially if you follow a meaningful instruction. The initial task is to determine the required amount of materials for purchase. If we are talking about classic tiles and layers of plaster, the master should calculate the area of the surface to be decorated, not forgetting about the inter-tile seams (1.5-2 cm are laid on them). The next step is to select the right tools:

-

mounting reinforcing mesh;

-

hammer with rubber tip;

-

chisel and hammer drill;

-

heat-resistant glue;

-

tile cutter;

-

metal profiles and spatulas;

-

bubble or electronic level;

-

grouting compound;

-

grinding machine;

-

fasteners that allow you to secure the crosses to the guides;

-

primer for adhesion;

-

seam crosses.

The entire range is purchased literally at one time, in any specialized hardware store.

Step-by-step guide

The key to successful work is careful and comprehensive preparation. The surface of the furnace walls is cleaned of dirt, impregnated with a primer and covered with a pre-selected heat-resistant plaster composition. Hammers, chisels, drills and drills are used to remove old finishing elements (if any, of course). As soon as the starting masonry has completely dried, the master should proceed to cladding.

Step No. 1. Cutting the surface of the tile for cladding the furnace and diluting the glue

Using a special tile cutter, we separate the panels according to a pre-selected pattern. The profile device can be replaced with an ordinary grinder, with the correct disc attachment. The adhesive composition is diluted exclusively according to the instructions – the recommendations are printed directly on the bags with the building material.

Step No. 2. Forming the base plane

We start working from the bottom, laying an even beaten line on the lower edge of the panels, according to a laser or bubble building level.

We pay special attention to the degrees and deviations, since the quality of further work directly depends on the operation of installing the starting row.

Step No. 3. Facing subsequent rows

We act in a similar order – we apply tile adhesive to the panel, and then apply it to the working surface. Between the lines we install special construction crosses, allowing us to maintain the same size of the seams.

Step No. 3. We perform alignment

The plaster layer must also be aligned exclusively using an electronic or bubble level. If the appropriate tools are not available, the master uses an ordinary plumb line. The panels are pressed deep using a mallet – a small hammer with a rubber knob. The specialist covers the area exclusively in this order. First, he forms the planes, and then begins to install the tiles in them.

Step No. 4. Filling the seams

At this stage, you will have to use a special, pre-selected and purchased fireproof grout. The component is placed in the seam area, and then leveled using a spatula or a small roller.

There are no difficulties in such work. The main task of the master is to maintain the level – that is why he should move away from the stove as often as possible and visually inspect the surface. Any deviations and distortions will lead to the fact that a potentially beautiful structure will lose all aesthetics.

Video instructions for beginners

Before starting to install ceramic, terracotta, tile or granite panels, the owner of a stove that runs on coals and logs should familiarize himself with all the nuances of the upcoming work process.

This can be done using instructions published on the Internet. The best way to get information is to watch specialized videos. Fortunately, popular hosting sites have enough manuals edited by experienced tilers.

Beautiful examples

In order for the result of the facing work to exceed all possible expectations, a novice craftsman needs to pay attention to examples of other, truly correct and stylistically verified solutions.

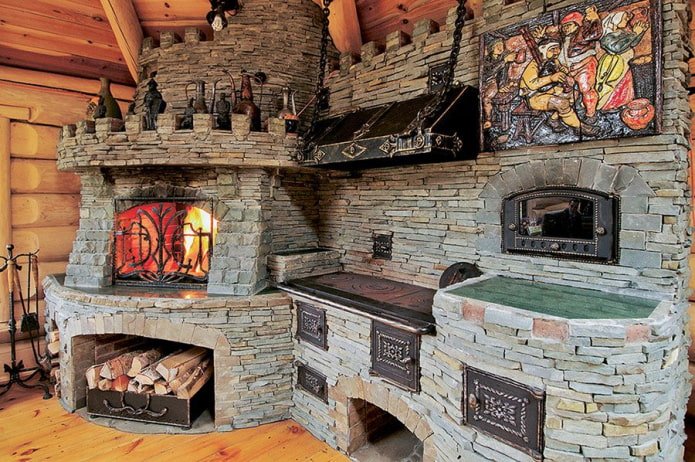

Within the framework of this design project, the stove acts as a kind of island – the central zone of visual attention. It also has an applied character – it is used for cooking and high-quality heating of the living room / dining area.

Here is an example of a classic Russian stove, with elements of painting and artistic framing, realized with the help of facade bricks. The module divides the room into two zones — a functional living room and a small nook for storing various household items.

A modern style fireplace that easily fits into an exclusively modern interior. The brick finishing panels of the stove are complemented by fireclay floor tiles that imitate a traditional Venetian granite base.

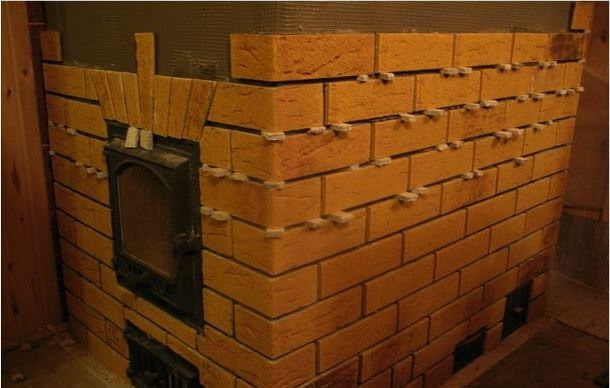

A stove design with an exclusively practical character. Suitable for both heating various home rooms and for cooking. The stove finish is a combination of clinker tiles and bricks.

The most massive structure, designed primarily for powerful heating. The decorative element is classic masonry brick, refined with functional elements – dampers, air regulators, a small glass frame, etc.

Now reading:

- Gas stove in the kitchen (33 photos): unique solutions and design tips.

- 14 Advantages and Disadvantages of Frame Houses, Including Controversial Aspects

- Ford Focus: A Compact Car with Style and Performance

- Floating stretch ceilings: over 60 photos and ideas with side lighting.

- Discover the Versatile Fiat Scudo Van